TUMBLING TYPE MIXERS

PMS VEE, CUBE, AND DOUBLE CONE MIXERS

Tumbling Type Mixers are suitable for gentle blending of dense powder and granules. It has been recognized as an economical tumbler with its durability and minimum maintenance requirement.

PMS provides a wide range of Tumbling Type Solid Mixers, including Cube Mixers, Vee Mixers, and Double Cone Mixers. These mixers utilize rotation around a central axis to blend materials thoroughly and uniformly. They are suitable for gentle blending of dense powder and granules and have been recognized as highly efficient and cost-effective tumblers due to their durability and minimum maintenance requirements. Our product series encompasses systems that operate on a laboratory to a production scale, with working capacities ranging from 10 to 2,000 liters.

TYPES OF TUMBLING MIXERS

PMS CUBE MIXER CB 100

PMS DOUBLE CONE MIXER DCM30

PMD VEE MIXER V30

THEORY OF OPERATION

PMS Vee, Cube and Double Cone Mixers are tumbling type mixers in which motion is imparted to the powders by rotating the vessel containing the powder about an axis. With each rotation, the powder mass is alternately divided and recombined, thereby providing an efficient intermeshing effect. Blending action can be sustained more thoroughly throughout all parts of the powder bed. In addition, an agglomerate breaking bar, located in the blender rotational axis, helps improving agitation of powder bed.

All contact parts, including Mixing Chamber, agglomerate breaking device and inlet port covers, are made of stainless steel SUS AISI 304 and mirror polished. Product contact parts are completely separated from technical components, assuring oil and grease free in the operating chamber. Secured inlet port covers and outlet port butterfly valve ensure dust tight operation.

The raw material is fed through top inlet ports by simply unclamp the inlet port cover. Once the material is properly mixed, unload finish product through bottom discharge port into product container. For process reproducibility, mixing time can be set to determine process end-point. Process could not be started unless safety guard is firmly closed.

APPLICATION

Pharmaceuticals: Powder, Granules, Pellets, Herbal Medicine

Cosmetics: Face powder, Body powder

Food: Seasoning, Health food, Flavor, Candy, Additives, Confectionery, Spices, Sugar, Salt, Starch

Agricultural: Animal Feed, Premix, Pesticides, Fertilizers

Chemical: Plastic powder, Polyester chips, Pigments and Color concentrates, Dyes, Resins

Other: Metal powders, Paints, Detergents, Minerals

BENEFITS

cGMP Compliance: Ensure the safety and quality of products produced

Energy Efficient: Tumbling Mixers are designed to provide efficient and effective mixing of powders, or other solid materials contained.

Reproducible of Product

Easy to Scale Up and Down

Durable Machine Component

Safe and Clean Working Environment

Easy to Operate, Clean and Maintenance: It requires a litter training to be used proficiently.

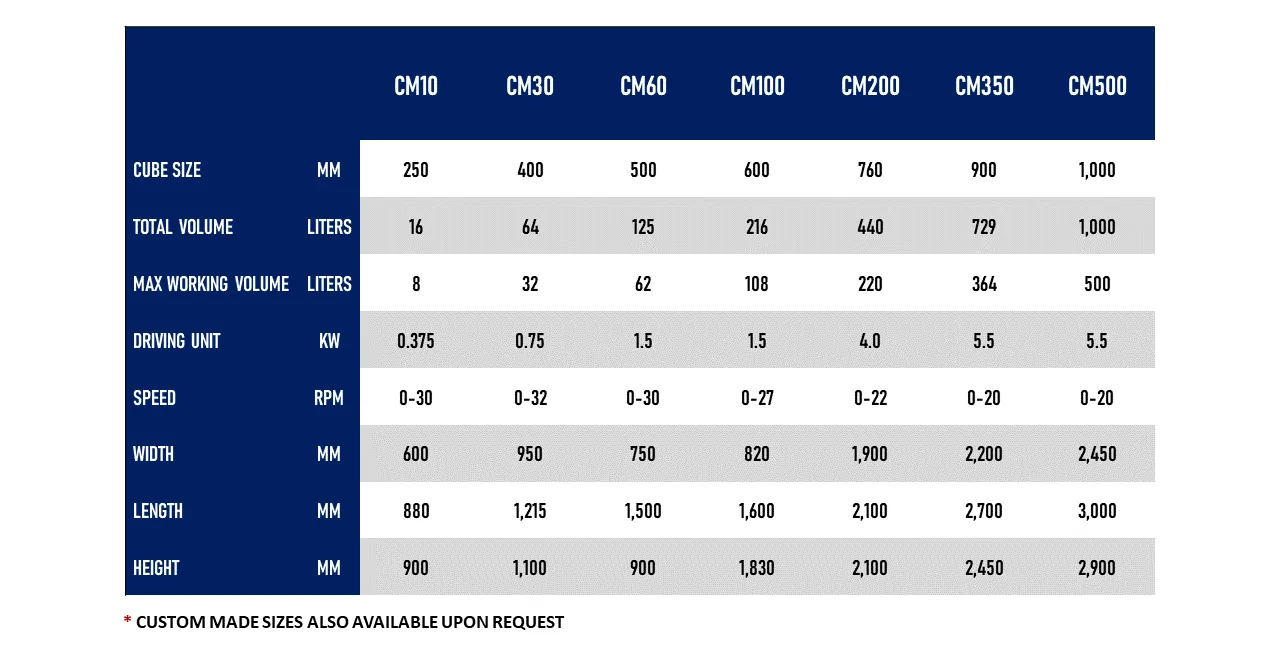

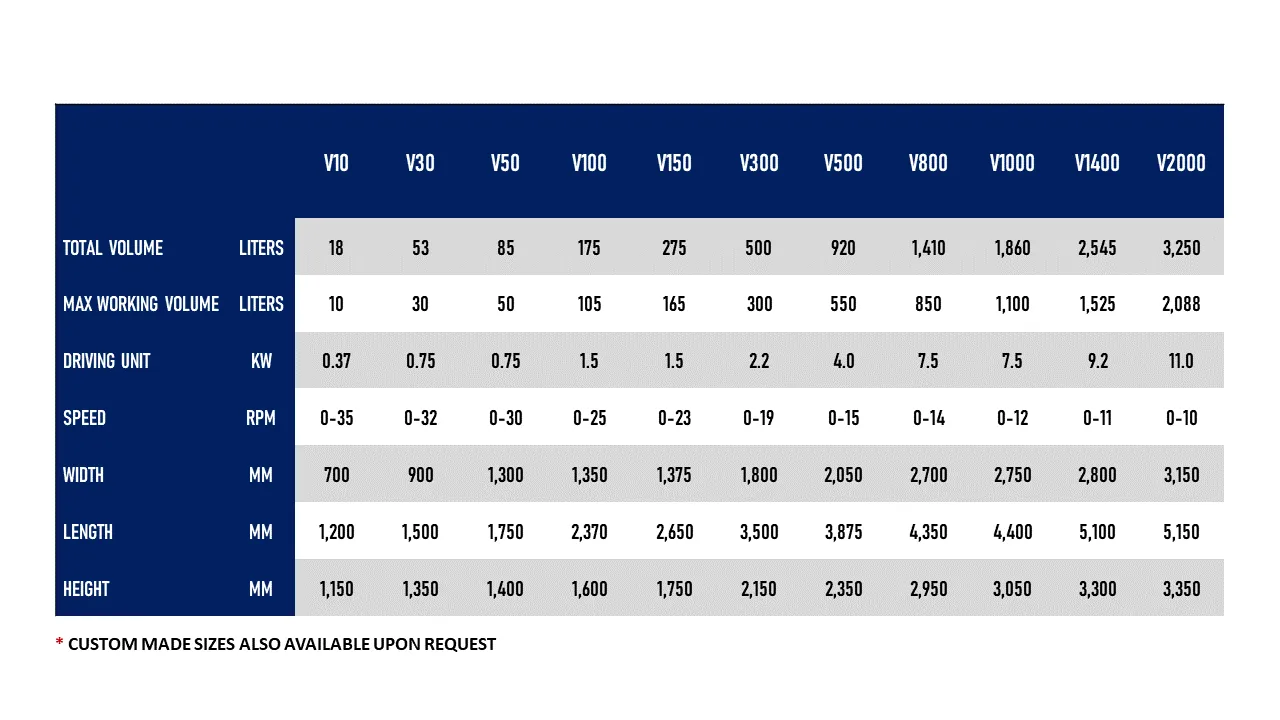

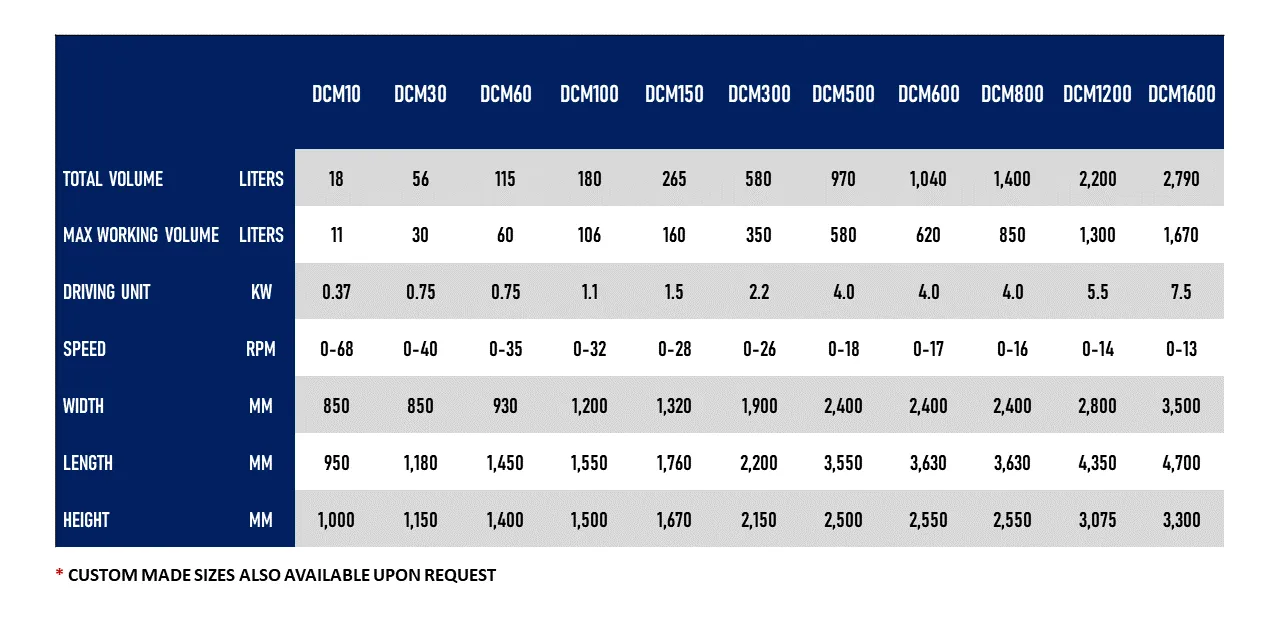

SPECIFICATION

CUBIC MIXER

VEE MIXER

DOUBLE CONE MIXER

STANDARD

All contact parts made of stainless steel SUS 304

One set of agglomerate breaking device, made of stainless steel SUS 304

Machine stand made of Enamel-painted Carbon steel dressed with Stainless Steel AISI 304, Platform and ladder made of Stainless Steel SUS AISI 304

Single Speed, non-explosion proof geared motor

Discharging port with manual butterfly valve

Alarm for interlocks and process abnormalities integrated with system, with acknowledgement for respective alarms by operating personal

Safety guard located in front of the machine

Commissioning Report

OPTIONS

All contact parts made of stainless steel SUS AISI 316

Customized Height to Match Specific Discharge Requirements

Variable Speed Drive

Explosion Proof Motor / Control

Wash in Place (WIP) or Clean in Place (CIP)

Programmable Logic Control and HMI

Special design for loading system, i.e. Vacuum transfer unit or in-line operation

Validation Document: Installation Qualification (IQ)/ Operational Qualification (OQ)

CFR 21 Part 11 Audit trail Compliance

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved