PMS VACUUM FEEDER

Vacuum Transfer Machines

PMS Vacuum Transfer Machine is an efficient solution for transferring materials from one process to another in a contained and dust-free environment. The vacuum transfer system is suitable for a wide range of applications in the pharmaceutical, chemical, and food industries. The machine is designed to handle powders, pellets, and granules of various sizes, and it can be customized to suit specific requirements. Vacuum Transfer Machine helps to maintain a clean and safe working environment by preventing contamination and dust emissions during material transfer.

The machine offers several other advantages. Firstly, its enclosed design ensures the containment of materials during transfer, minimizing the risk of cross-contamination and maintaining product integrity. The machine operates on a closed-loop system, effectively preventing the release of dust particles into the surrounding area, thereby enhancing worker safety and reducing the potential for respiratory hazards. PMS offers two model of Vacuum Transferring System -- Vacuum Feeder and Vacuum Blower.

PICTURE OF VACUUM FEEDER

THEORY OF OPERATION

Using the gas ring vacuum pump, the air is pulled through the fabric filters to create the vacuum in the chamber, which will convey the materials from the remote location via flexible hose into the chamber. Then, the materials will be transferred into the container or machine through the feeding port. Alternatively, when the vacuum will be created in through the pipeline, which will transfer the product into the powder container. This system is also called Low Density Vacuum Conveying System, which is most suitable for non-abrasive, fine, low bulk density, fibrous, and large light particle materials.

To ensure the stable efficiency of the conveying process, the feeder is enhanced with the electro-pneumatic filter cleaning mechanism. PMS Vacuum Feeder® can transfer the material up to one hundred kilograms per 5 – 10 min (depend on product density). The remaining waste product can be remove from the feeder (through bottom butterfly valve) is attached for disposing of the remaining dust from the filters.

This principle totally separates the product from the moving parts. Therefore, it prevents the material handing from contamination. In addition, all contact parts are made of stainless steel, which is compliance to cGMP standard.

APPLICATION

BENEFITS

cGMP Compliance: Ensure the safety and quality of products produced

Energy Efficient and Fast Process Time: Reduce material handling time

Reduce Contamination: Vacuum Transfer can ensure that

Safe and Clean Working Environment

Easy to Operate, Clean and Maintenance: It requires a litter training to be used proficiently.

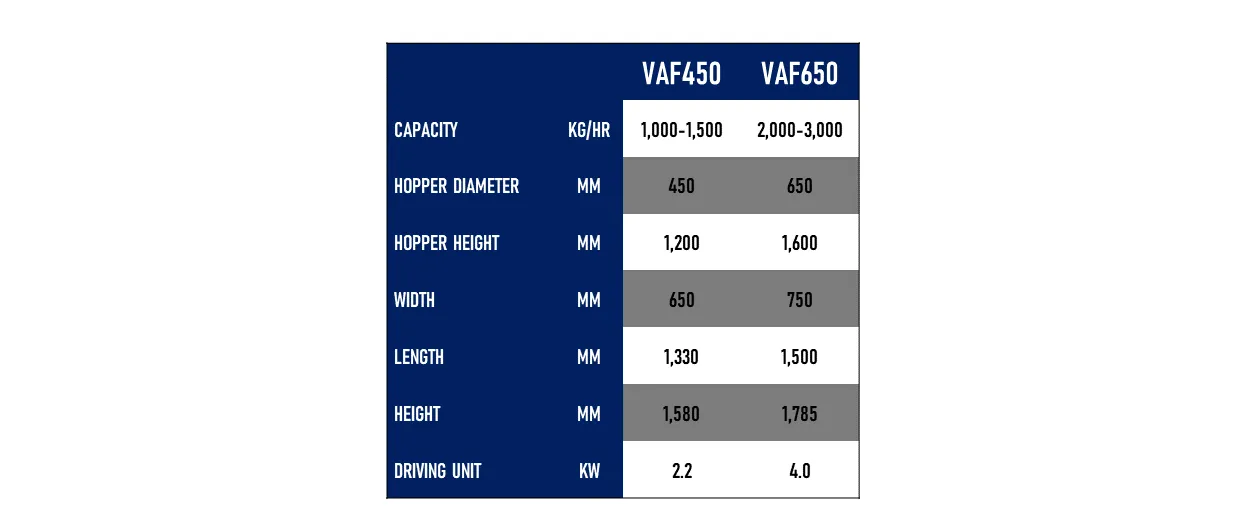

SPECIFICATION

STANDARD

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved