PMS VACUUM CREAM MIXER

Vacuum Homogenizing Cream Mixer

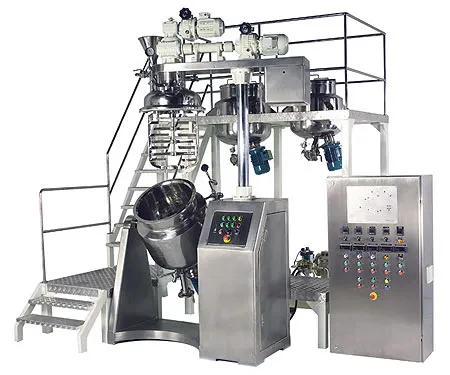

PMS Vacuum Cream Mixer® offers a combination of counter-rotating paddle agitator and internal homogenizer. Gate-type agitator with cross baffles rotates in anti-clockwise direction while counter paddle revolves in clockwise direction, generating a disturbance in the normally circular flow pattern and dampen vortex formation.

PMS Vacuum Cream Mixer applicable for a wide variety of viscosity product, i.e. emulsions and semisolid. It integrates mixing, vacuuming, heating, cooling and homogenizing functions into single machine, resulting in a considerably reduction in cycle time.

The machines can be used in a number of industries, including Pharmaceutical, Cosmetic, Food and Chemical Industries. Our range stretches from laboratory model of 10 liters up to production model of 6,000 liters working capacity.

SOME HIGHLIGHTED FEATURES & OPTIONS

Standard Agitator and Counter Rotating Blades are working together to rapidly mix the ingredients

Bottom Homogenizer that can be selected to Low, Medium and High Viscosity

Optional Hot Water Circulation Tank for heating of the ingredients, when you don't have the Steam for Heating.

Touch Screen HMI to ease the Controlling of the Vacuum Cream Mixer. It is also enable the recording function of the parameters.

Hydraulic to Lif

Oil Phase and Water Phase can be an optional to the Vacuum Cream Mixer to fasten the Process.

THEORY OF OPERATION

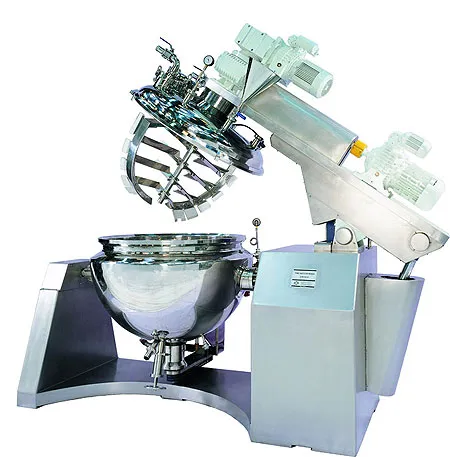

The basis of mixing system of PMS VACUUM MIXER® is a combination of counter-rotating paddle agitator and internal homogenizer. Gate-type agitator with cross baffles rotates in anti-clockwise direction while counter paddle revolves in clockwise direction, generating a disturbance in the normally circular flow pattern and dampen vortex formation. The blades of paddles are pitched to promote top-to-bottom flow. In addition, adjustable scrapers are utilized to prevent the build-up of a stagnant film between the agitator and the vessel, and assure efficient heat transfer to product during heating and cooling steps. The speed of the agitator and the counter paddle can be varied separately.

Homo disperser, locates at the bottom of the vessel, accomplishes emulsification by physical action and centrifugal forces created by high-speed rotation of the rotor. These actions would break up oil phase/ aqueous phase liquid stream into tiny and discrete droplets. Then, they will be intensively and continuously mixed by counter-rotating agitator mechanism, and become final products. For versatility of use, interchangeable high viscosity and low viscosity homo disperser heads are provided with the system. Homo disperser speed is adjustable by inverter control.

Conical mixing vessel is jacketed for heating/cooling and completely enclosed. All contact parts are stainless steel SUS 316. The vessel is designed to operate under vacuum; mixing and emulsification can then be performed without entrainment of air.

A temperature measuring probe, extending directly into the product, allows exact setting of the temperature with a view to process management. For process reproducibility, mixing time, product temperature, agitator speed, counter paddle speed and homogenizer speed can be controlled to the desired condition.

Raw material feeding to PMS VACUUM MIXER® can be manual through the fully open lid, or completely automatic through vacuum system. Finished product is discharged by manual discharge valve or through special design transfer pump on mobile trolley into product container.

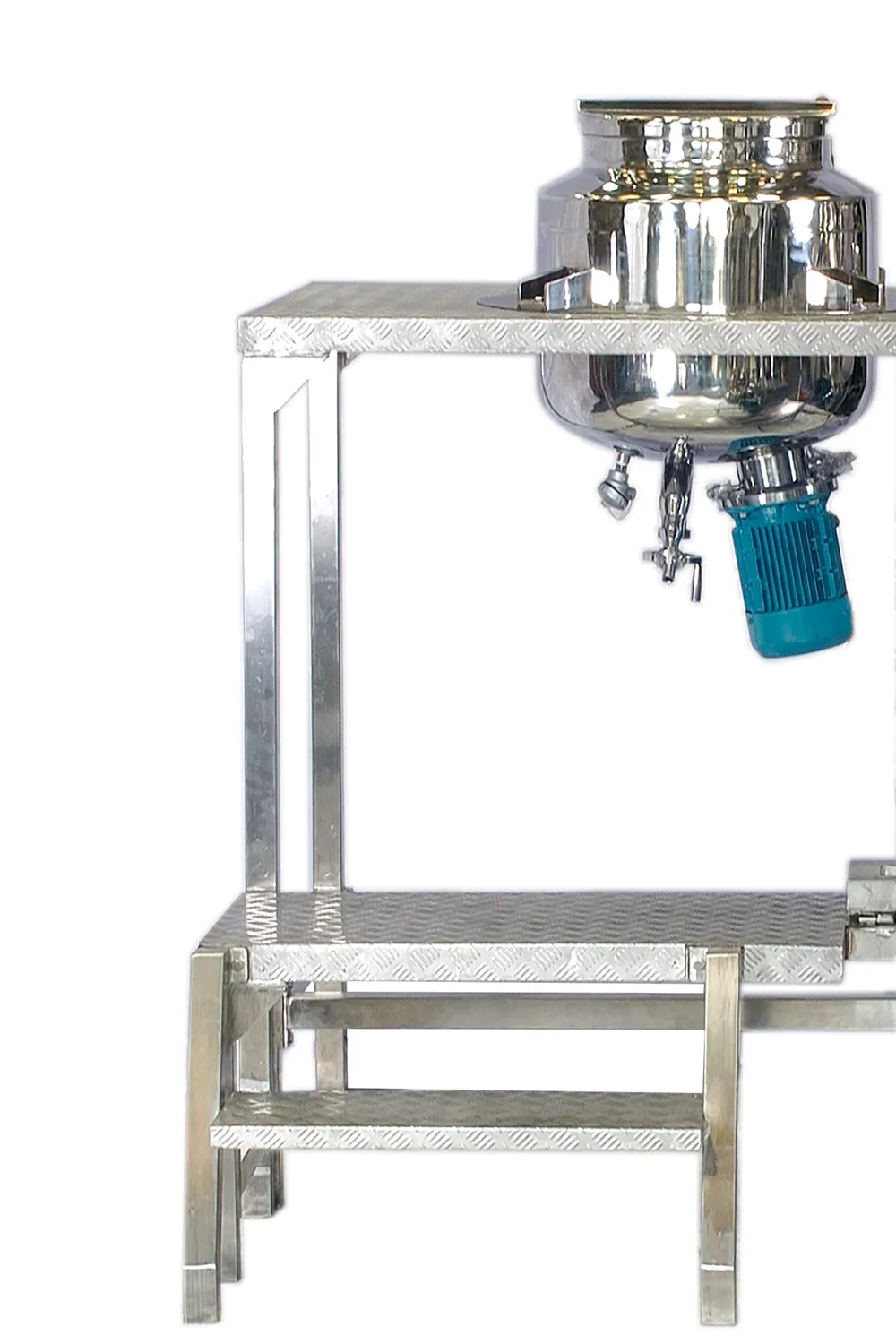

Special Design for Low Head Room

APPLICATION

Pharmaceutical: Vacuum homogenizing mixers play a crucial role in pharmaceutical manufacturing processes. They are utilized for the production of ointments, creams, gels, and other topical formulations. The mixers ensure efficient blending and dispersion of active pharmaceutical ingredients (APIs) and excipients.

Cosmetics: Apart from cosmetics and skincare, which is quite obvious. PMS Vacuum Cream Mixers are also used in the production of a number of personal care products, including hair care products, body washes, shower gels, and shaving creams. They aid in achieving a uniform blend of ingredients, enhancing product performance and aesthetics.

Food and Beverage: Vacuum homogenizing mixers are used for the production of food and beverage products, such as sauces, dressings, mayonnaise, emulsions, and dairy products. They can help in achieving a smooth and homogeneous texture, enhancing product stability and quality.

Chemical: In the chemical industry, vacuum homogenizing mixers are employed for the production of various products like paints, coatings, adhesives, lubricants, and specialty chemicals. They facilitate the uniform mixing and emulsification of different components, ensuring consistent product quality.

BENEFITS

cGMP Compliance: Ensure the safety and quality of products produced

Versatility and Flexibility: PMS Vacuum Cream Mixers are versatile and can handle a wide range of viscosities and formulations. They can process various product types, including creams, lotions, gels, serums, and emulsions, making them suitable for multiple applications in different industries.

High and Uniform Product Quality: The uniform mixing and granulation achieved by PMS Vacuum Cream Mixer results in superior quality products with consistent product quality.

Easy to Operate, Clean and Maintenance. The mixers are designed with hygiene and ease of cleaning in mind. Many models have features like detachable parts, CIP (Clean-In-Place) systems, and smooth surfaces, making them easy to clean and maintain. This ensures product safety and minimizes downtime during cleaning procedures.

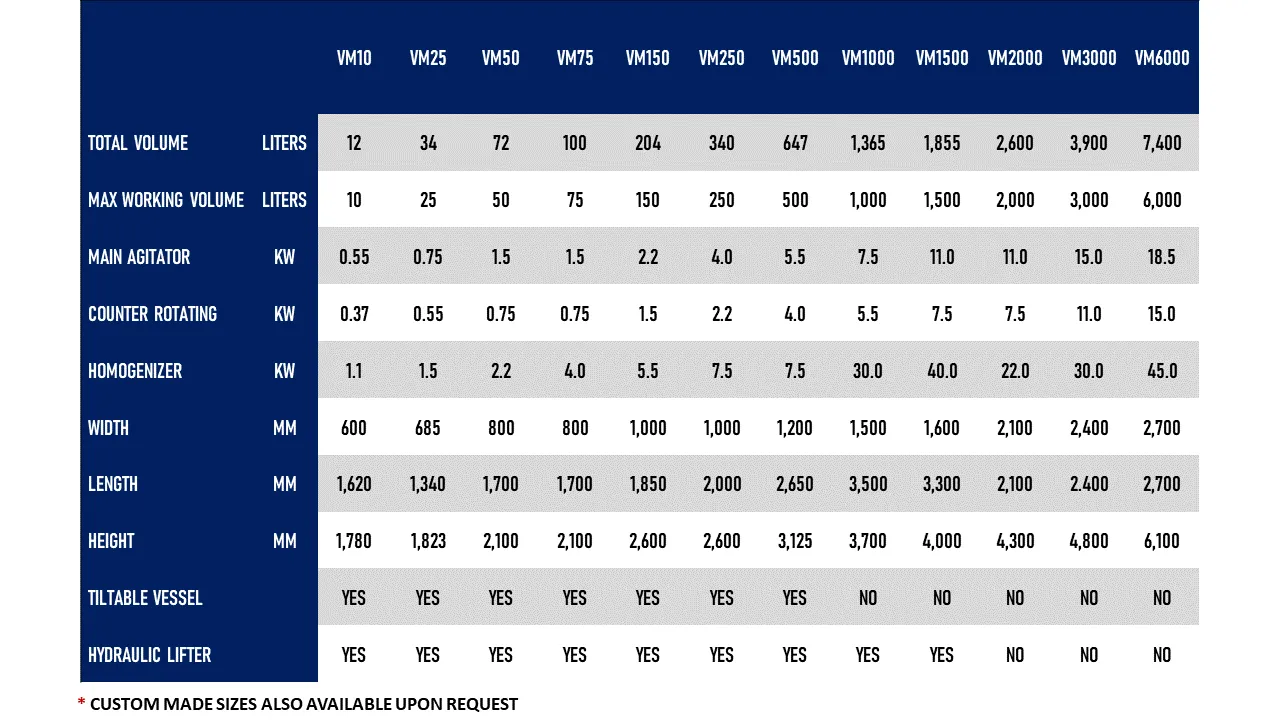

TECHNICAL DATA

STANDARD

Mixing bowl with heating/cooling jacket and all contact parts made of stainless steel SUS 316

Variable-speed main agitator, counter-rotating mixer and homogenizer.

Homogenizer located at the lowest point in the vessel for internal homogenization

Changeable Low viscosity homogenizing head and High viscosity homogenizing head

Integrated vacuum pump and vacuum equipment with manual control

Tiltable vessel to discharge product or clean for model VM 10 N – VM 500 N

Semi-automatic control system and Safety equipment

Manually operated valves

Commissioning Report and Manual

OPTIONS

Explosion-proof motors and Explosion-proof control

Oil phase and water phase mixing tank with special design platform to suit plant layout

Hot water circulation system for heating purpose

Special loading equipments or dosing unit

Discharge height and Feature to suite specific discharge requirements, i.e. Product transfer pump with mobile trolley

Automatic Control System with Pneumatically operated valves

Programmable Logic Controller (PLC)

Explosion Proof Motor / Explosion Proof Controller

Washing in place (WIP)/Cleaning in place (CIP) system

Validation Document: Installation Qualification (IQ)/ Operational Qualification (OQ)

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved