hammer mill

PMS Hammer Mill

PMS Hammer Mill® is a machine that primarily uses impact forces to break down and reduce the particle size of dry materials. It is a popular choice for the fine grinding of materials and is capable of processing both wet and dry granulations and dispersing powder mixtures.

The particle size and throughput of the ground material are determined by several factors, including the rotor speed and the size of the screen used in the machine. The hammers are the primary impactors that strike the material, while the rotor speed determines the frequency and intensity of these impacts. The size of the screen used in the machine determines the size of the final product, as smaller screens produce finer particles while larger screens produce coarser particles.

Overall, this machine is a versatile machine that can be used in a variety of applications, including food processing, mineral processing, and chemical industries, among others, to break down and reduce the size of dry materials.

SHOW CASE

THEORY OF OPERATION

The feed material is presented into PMS HAMMER MILL® through adjustable-angle feeding tray or through feeding chute. Swinging blades are affixed to a high-speed rotor mounted in a chamber. The chamber is bounded on the bottom by an interchangeable screen through which the milled material must pass. The rapidly rotating hammers strike against the feed material, breaking it into smaller fragments, which are swept against the screen. Particles, that are small enough to pass through the screen, drop through the discharge chute into a collection container.

Type of hammer, rotor speed and size of the screen openings are important factors governing the particle size of the product. Flat-edge hammers are generally used for pulverizing and tend to create a large number of fines. Knife-edge hammers are generally used for chopping and sizing when fines are undesirable or when fibers and tissues must be severed.

Product particle size varies for a given screen according to the rotor speed. The discharge product is actually smaller than the nominal dimensions of the screen opening. Finer particles are produced with a given grid at higher speeds.

The driving is through belts and pulleys. The bearing and seal design in such a way that no contamination from driving unit would enter the processing chamber. The motor and mill assembly are mounted on a common baseplate which carries the ground product discharge chute and a rigid support frame, resulting a compact design configuration.

APPLICATION

Pharmaceuticals: Grinding of Active Ingredients, Reducing Particle Size of Excipients, Preparing Powder for Inhalation

Herbal Products: Grinding Herb and Plant Material, Reduce Particle Size of Herbal Extracts, Preparing Herbal Powder

Food: Grinding of Spices, Sugar, Sweetener, Dried Food, and Coffee Beans

Agricultural: Grinding Grains, Hay, Straw for Animal Feed, Shredding Agricultural by Products to Make Biomass Fuel

Others: Grinding Plastic for Recycling, Grinding Fish Bone for Animal Feed

BENEFITS

cGMP Compliance: Ensure the safety and quality of products produced

Energy Efficient and Fast Process Time: PMS Hammer Mill are design to operate efficiently with minimum energy input. Each unit can process up to 500 kg / hour depending on Material.

Versatility Mixing Process: Can be used for wide range of applications including crushing, grinding, shredding and pulverizing a variety of materials.

Uniform Size: Hammer Mill are effective at producing a uniform particle size distribution, which is important for some applications, such as pharmaceuticals or food products.

Low Cost of Ownership: Hammer Mill is one of the affordable grinder and crusher to be used for small scale operation.

Easy to Operate, Clean and Maintenance: It requires a litter training to be used proficiently.

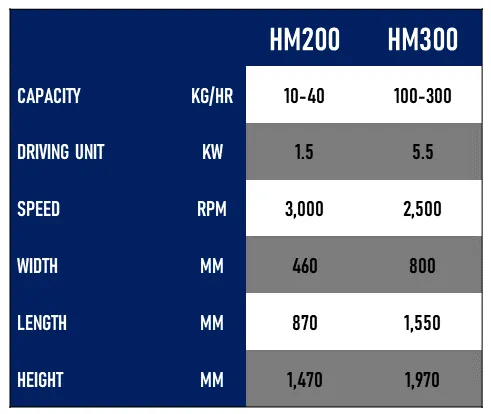

SPECIFICATION

STANDARD

Contacted Parts are made of Stainless Steel 316

Variable Speed using Inverter

Explosion Proof Motor / Explosion Proof Controller

Inert Gas Blanketed for Hazardous Material

Product Container

Installation on Platform

Additional Stainless Steel Screens

Special Loading and Discharge Features

Validation Documents: Installation Qualification / Operational Qualification

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved