CONTAINER BLENDER

PMS IBC (Intermediate Bulk Container) Blender

PMS Container Blender®, which is normally known as intermediate bulk container (IBC) mixing system, is a mixing system that is widely used within pharmaceutical manufacturing process. This type of mixer can be used as storage, transport, and mixing vessel, which reduces the complication of the conventional mixing processes that require a number of containers for the whole process.

A container blender is widely used in pharmaceutical, food, and chemical industries. This type of blender is designed to blend powders, granules, and other materials inside an IBC. One of the key advantages of a container blender is its ease of use. The IBC is loaded onto the blender, and the mixing process begins automatically, saving valuable time and labor. The blender is also equipped with advanced control systems, allowing for precise and consistent mixing. Container blenders are designed to be easy to clean and maintain, making them a cost-effective solution for many applications.

SHOW CASE FOR SMALL SPACE (UP TO 400 L.)

THEORY OF OPERATION

PMS Container Blender’s mixing system is the optimal solution for applications that require high levels of product purity or those involving hazardous, corrosive, or toxic ingredients, since the container completely sealed mixing chamber, providing an fundamentally safe, emission-free processing environment.

While mixing, a well-secured container is rotated in a supporting frame around diagonal axis. The angular arrangement and rotation allows the product to be mixed within three-dimensional environment, without using any moving mixing tool (Tumbling System). This mechanism allows the mixing process to be done with very low shear force. As a result, the product characteristics remain almost unchangeable. In addition, the speed of the rotation can also be adjusted. Therefore, the process can be adapted to match various product characteristics, including granulated substances.

Before mixing, the container will be placed horizontally into mechanical clamp. Then the container will be lifted by the pneumatic (for medium size) or hydraulic (for large size) . After mixing, the container with mixed product will be moved down and remove. The new container can be placed immediately. This allow increasing capacity when compare to conventional tumbling system.

APPLICATION

Pharmaceuticals: Powder, Granules, Pellets, Herbal Medicine

Cosmetics: Face powder, Body powder

Food: Seasoning, Health food, Flavor, Candy, Additives, Confectionery, Spices, Sugar, Salt, Starch

Agricultural: Animal Feed, Premix, Pesticides, Fertilizers

Chemical: Plastic powder, Polyester chips, Pigments and Color concentrates, Dyes, Resins

Other: Metal powders, Paints, Detergents, Minerals

BENEFITS

cGMP Compliance: Ensure the safety and quality of products produced

Energy Efficient: Container Blender are designed to provide efficient and effective mixing of powders, or other solid materials contained within intermediate bulk containers. They utilize various mixing techniques, such as Paddling and Tumbling System

Cost Saving: Container Blender allows for faster and more efficient blending of materials. This can lead to significant time savings and increased productivity, comparing to other Tumbling Mixers.

Reduced Contamination and Operation Safety: Container Blender reduces the risk of cross-contamination, as the mixing process occurs within a sealed container. This is especially important in hygienic industries.

Easy to Operate, Clean and Maintenance: It requires a litter training to be used proficiently.

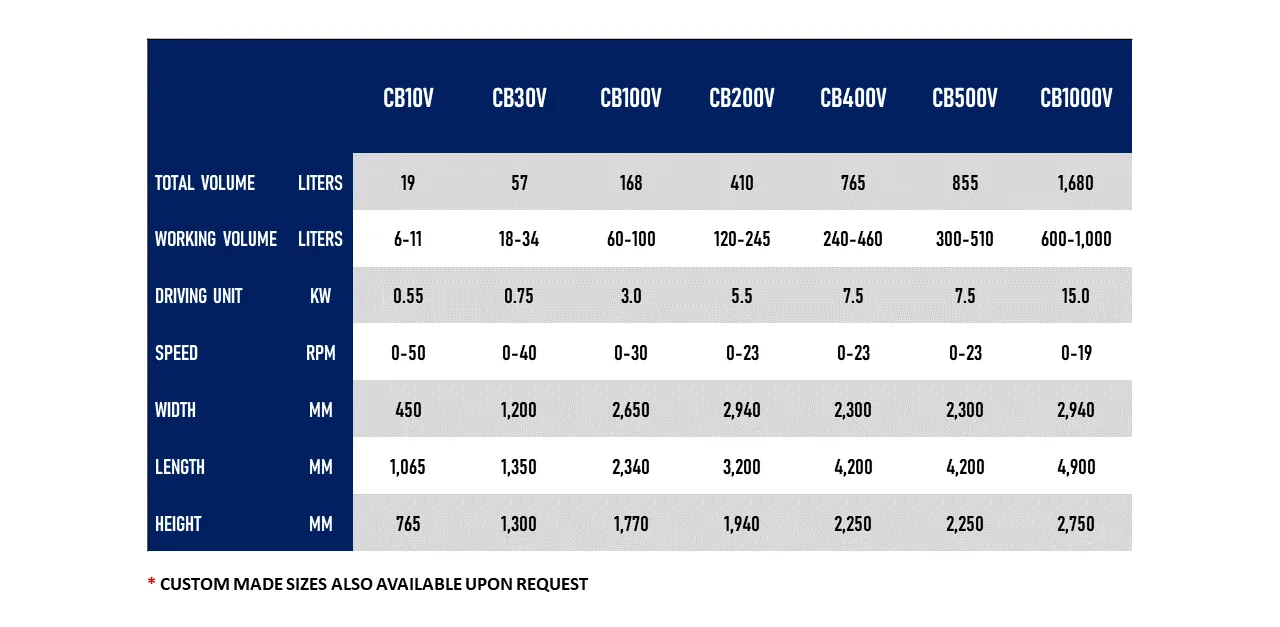

SPECIFICATION

STANDARD

All contact parts made of stainless steel SUS 316

One set of agglomerate breaking device, made of stainless steel SUS 304

Clamping device to hold container with driving shaft

Variable Speed, non-explosion proof geared motor

Electrical control box with semi-automatic control system and safety devices

Safety guard located in front of the machine

Commissioning Report

OPTIONS

18/88-89 M.6 Khok Krabue, Mueang

Samut Sakhon, THAILAND 74000

Phone: +66 2 284 2159 TO 62

Email: [email protected]

© 2020 PMS. All Rights Reserved